Why CHARM?

When inputs from different fields are processed together in a commingled system, for example on an offshore oil platform, it is important to ensure that each field is allocated its fair share of hydrocarbons for both financial and reservoir management purposes.

Hydrocarbon allocation involves a complex mathematical calculation to determine the quantity of oil and gas products that come from each field or well, and thus determine their ownership.

Rigorous and representative allocation reduces the exposure of companies to financial and reputational loss from misallocations. The results from an allocation can be input to reservoir models, allowing engineers to optimise production and make decisions on drilling new wells.

Theory vs practice : how traditional simulation models are used in hydrocarbon allocation

Process simulation packages, such as HYSYS and PRO/II, have been widely used in the oil and gas industry for process optimisation and design. As they determine how hydrocarbons behave in a process plant they have been used to calculate shrinkage factors and to predict physical properties, etc. However, there are issues that militate against their use in allocation systems:

- Model complexity and stability: simulation packages are built to model a wide range of processes. Such models are complex and frequently require a Process Engineer to ensure they solve;

- Software integration: neither allocation nor simulation software are developed to talk to each other;

- Software updates: if an interface between allocation and simulation software is implemented, then routine updates of vendor software can render the interface non-functional;

- Even when a general purpose simulation package is used, the nature of the interface and package overheads often mean that allocation runs take several minutes each making reruns as a result of corrections to historic metering values a time consuming exercise.

These issues mean that Operators resort to alternative approaches, such as running the simulation off-line and transferring results from the simulation to the allocation system. In reality, some simulations are not updated and the frequency of data transfer may be arbitrary. It is far more desirable to use the simulation every day (or even hourly) in order to capture changes in the process.

Another alternative is to curve fit empirical correlations to simulation data in an attempt to mimic the simulation results in the allocation system. Such correlations are only approximations of the simulation and only applicable over the range of conditions for which they are fitted. Failure to anticipate all potential production scenarios can produce spurious results.

CHARM : the accuracy of process simulation easily integrated into hydrocarbon allocation

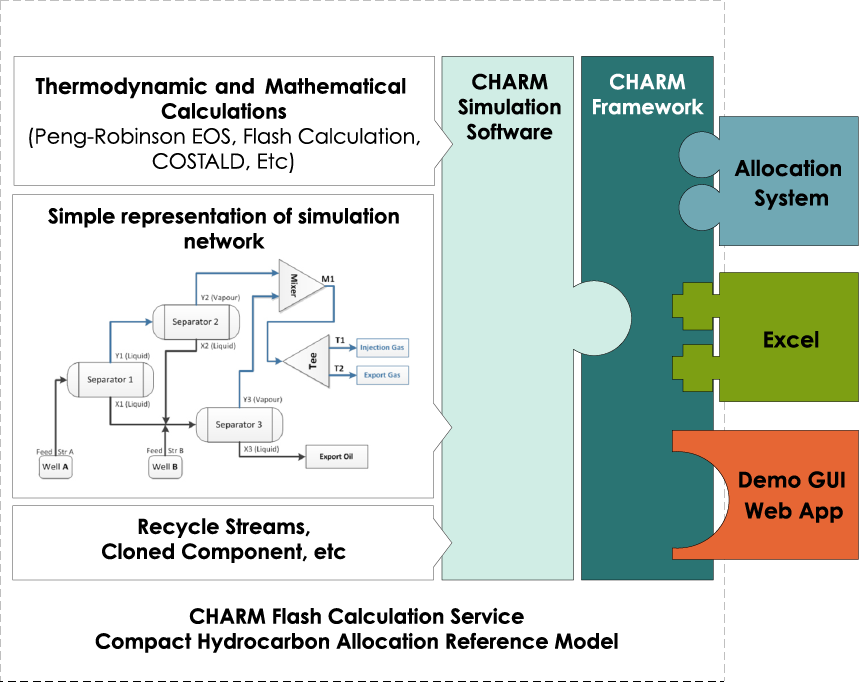

CHARM can be readily integrated with allocation software systems with a substantial cost saving. CHARM quickly solves the equations necessary to determine how hydrocarbons move through the process, by using the same industry standard equations, such as the Peng-Robinson equation of state, to model the vapour-liquid equilibria in the various separators.

CHARM easily integrates with hydrocarbon allocation software via interfaces which use XML to pass the properties of hydrocarbon elements, the vessel connectivity (i.e. the process topology between the various separators, mixers, etc.), the separator temperatures and pressures, and feed flows.

CHARM has been extensively validated by comparing the results of the calculations to those from HYSYS for a variety of process networks.

CHARM focusses on modelling for allocation purposes and has a number of key benefits including robustness, flexibility and auditibiity but most importantly, the ease of software integration overcomes the principle barrier to routine use of process simulation models in allocation systems.

Copyright © Accord Energy Solutions Limited